INSPECTION AND MEASURING

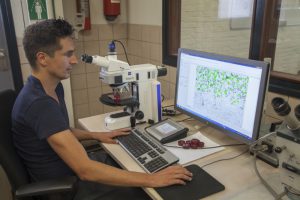

To guarantee top quality, we use the most modern inspection and measuring techniques, not only in our Laboratory & Measurement room but also in the production:

- the Laboratory performs metallographic examination and mechanical testing and is fully equipped for chemical analyses, tensile- and elongation testing, hardness testing and microscopical examination to analyse the structure of our material and products. We also have several X-ray machines to examine the products internally for inclusions and porosity. Furthermore we perform tests on the internal cleanliness.

- In the Production we perform continuous measurements in order to control our processes. Examples are temperature- , pressure- , geometrical-, gauges , fixtures , Spectrolab for chemical analyses of our material, X-ray- and leak testing equipment.

- The Measurement room performs measurements with high accuracy on tooling and products, among others with 3D CNC precision measuring machines. All measuring devices are registered , controlled and calibrated according to international standards.

When specified or necessary we inspect every single casting or assembly before it leaves our factory.

If applicable we hire renowned test institutes for specialised inspections or tests.